Industrial Cutting Press Machine Supplier & Manufacturer in Ahmedabad

Cutting Press Machine Supplier and Manufacturer

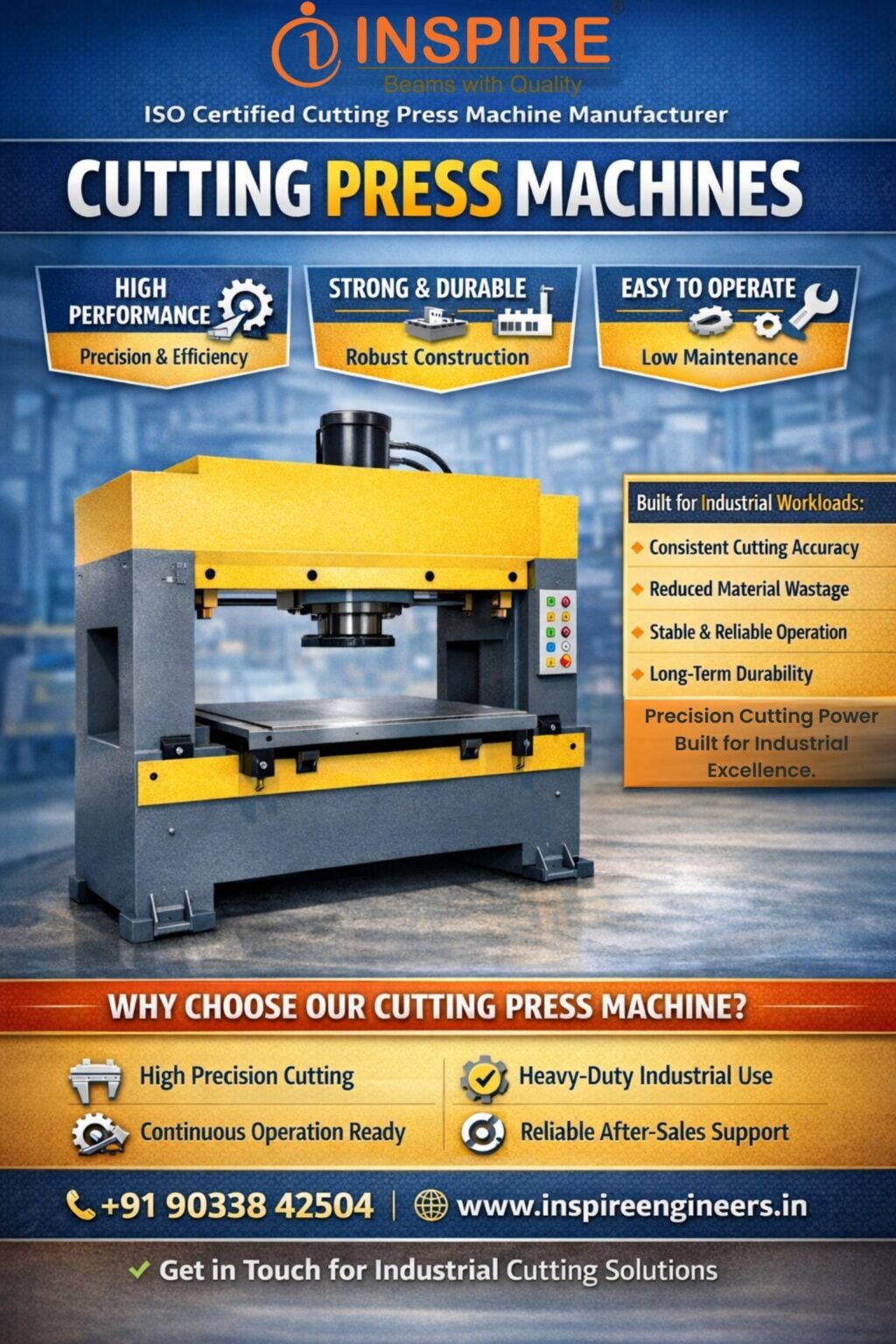

In today’s fast-moving industrial environment, precision, speed, and reliability are not optional—they are essential. Whether you operate in manufacturing, fabrication, packaging, or material processing, the right machinery directly impacts productivity, quality, and profitability. This is where Cutting Press Machine solutions play a critical role. At Inspire Engineers, we design and manufacture industrial cutting press machines that deliver consistent accuracy, long service life, and dependable performance under demanding conditions.

Based in Ahmedabad, Inspire Engineers has built a strong reputation as a trusted cutting press machine manufacturer and supplier in India. Our machines are engineered for continuous industrial workloads while maintaining cutting precision, operational safety, and energy efficiency. Because industries evolve rapidly, our designs also evolve—ensuring you stay competitive today and in the future.

Why Cutting Press Machines Are Essential in Modern Industries

Industrial operations demand repeatability and control. Manual cutting methods often result in inconsistent output, material wastage, and higher labor dependency. In contrast, a Cutting Press Machine automates the cutting process, ensuring uniform results every cycle. Moreover, automation reduces fatigue-related errors while improving overall throughput.

Additionally, cutting press machines support large-scale production without compromising quality. As industries scale, reliable machines become the backbone of efficient operations. That is why manufacturers across India are shifting toward precision-engineered cutting press solutions.

Cutting Press Machine Manufacturing Excellence at Inspire Engineers

Advanced Engineering Meets Practical Design

At Inspire Engineers, every cutting press machine is designed with a balance of innovation and practicality. Our engineering team focuses on mechanical stability, optimal force distribution, and user-friendly operation. As a result, our machines perform smoothly even during extended production cycles.

Furthermore, we use premium-grade raw materials and advanced fabrication techniques. This approach ensures structural strength, dimensional accuracy, and long-term durability. Each component is selected to withstand industrial stress while maintaining consistent output quality.

Heavy-Duty Construction for Industrial Reliability

Industrial environments are demanding. Therefore, our cutting press machines feature heavy-duty frames that minimize vibration and ensure stable cutting performance. Because stability directly influences precision, our machines are built to maintain alignment even under continuous operation.

In addition, reinforced mechanical structures reduce wear and tear. Consequently, downtime is minimized, and maintenance requirements remain low. Over time, this results in reduced operational costs and a higher return on investment.

Types of Cutting Press Machines We Offer

Hydraulic Cutting Press Machine Solutions

Hydraulic cutting press machines are widely used for applications requiring high pressure and uniform cutting force. These machines deliver controlled pressure, ensuring clean and accurate cuts across various materials.

Moreover, hydraulic systems allow smooth operation with adjustable force settings. As a result, manufacturers can handle different material thicknesses without compromising accuracy.

Mechanical Cutting Press Machine Systems

Mechanical cutting press machines are ideal for high-speed operations. Because they rely on mechanical power transmission, they offer faster cycle times. Therefore, they are suitable for industries where speed and volume matter most.

Inspire Engineers designs mechanical cutting press machines with precision-aligned components. This ensures smooth motion, reduced friction, and consistent output over long production runs.

Custom Cutting Press Machine Designs

Every industry has unique requirements. That is why we also offer customized cutting press machine solutions. From frame size to pressing capacity, we tailor machines to match your production needs.

By understanding your workflow, we design machines that integrate seamlessly into your existing setup. This customization improves efficiency while reducing unnecessary modifications later.

Key Features of Our Cutting Press Machine

Precision Cutting Performance

Accuracy defines a high-quality cutting press machine. Our machines deliver consistent cutting depth and clean edges. Because precision reduces material wastage, it directly improves cost efficiency.

Easy Operation and Safety-Oriented Design

Operator safety is always a priority. Therefore, our cutting press machines are designed with intuitive controls and safety mechanisms. This simplifies training while reducing operational risks.

Low Maintenance and Long Service Life

Industrial users prefer machines that require minimal upkeep. Our cutting press machines are engineered with durable components that reduce maintenance frequency. Consequently, you spend less time on repairs and more time on production.

Energy-Efficient Operation

Energy efficiency matters more than ever. Our machines are optimized to deliver high performance with controlled energy consumption. This helps industries reduce operational expenses while maintaining output levels.

Applications of Cutting Press Machines Across Industries

Manufacturing and Fabrication Units

Manufacturers rely on cutting press machines for shaping components accurately. Whether metal, rubber, or composite materials, consistent cutting ensures product uniformity.

Packaging and Processing Industries

Packaging industries demand speed and precision. Cutting press machines streamline cutting tasks, ensuring uniform packaging components that meet quality standards.

Automotive and Engineering Sectors

Automotive parts require exact dimensions. Cutting press machines help maintain tight tolerances, ensuring components fit perfectly during assembly.

Quality Assurance and Testing Standards

Strict Quality Control Procedures

Every cutting press machine manufactured at Inspire Engineers undergoes rigorous testing. From structural inspection to operational performance checks, each stage ensures reliability.

Moreover, safety tests confirm that machines meet industrial standards. This commitment to quality guarantees dependable operation in real-world conditions.

Continuous Improvement Through Feedback

We believe improvement is ongoing. Customer feedback helps us refine designs and enhance performance. As industries change, our machines evolve accordingly.

Why Choose Inspire Engineers as Your Cutting Press Machine Manufacturer

Proven Industry Experience

With years of experience in industrial machinery manufacturing, Inspire Engineers understands practical challenges. This knowledge allows us to design machines that deliver real-world results.

Trusted Supplier Across India

Our cutting press machines are supplied across India. Because reliability builds trust, our long-term client relationships reflect consistent quality and service.

End-to-End Support

From consultation to installation, we provide complete support. Even after delivery, our team remains available for guidance and service assistance.

Benefits of Investing in the Right Cutting Press Machine

Improved Productivity

Automation increases output while maintaining accuracy. A cutting press machine reduces manual effort, allowing faster production cycles.

Reduced Material Wastage

Precision cutting minimizes errors. Consequently, raw material usage becomes more efficient, lowering production costs.

Enhanced Operational Consistency

Consistency builds brand reputation. Cutting press machines ensure every unit meets quality standards, batch after batch.

Cutting Press Machine Maintenance and Longevity Tips

Regular Inspection and Cleaning

Routine inspections help detect minor issues early. Cleaning moving parts also improves performance and extends machine life.

Proper Operator Training

Well-trained operators handle machines efficiently. This reduces misuse and prevents unnecessary wear.

Scheduled Servicing

Periodic servicing ensures smooth operation. It also keeps components aligned and systems calibrated.

Future Trends in Cutting Press Machine Technology

Smart Automation Integration

Industries are adopting smarter machines. Integration with sensors and monitoring systems improves efficiency and predictive maintenance.

Sustainable Manufacturing Focus

Energy-efficient cutting press machines support sustainability goals. Reduced power consumption aligns with modern industrial practices.

How Inspire Engineers Supports Industrial Growth

At Inspire Engineers, we believe machinery should empower growth. Our cutting press machines are designed not only for current needs but also for future expansion. Because industries evolve, flexibility and reliability matter.

We work closely with clients to understand operational challenges. Then, we deliver solutions that enhance productivity, reduce downtime, and ensure long-term success.

Frequently Asked Questions About Cutting Press Machines

What materials can a cutting press machine handle?

Cutting press machines can process metals, rubber, plastic, leather, and composite materials, depending on configuration.

Are cutting press machines customizable?

Yes. Inspire Engineers offers customized cutting press machines based on capacity, size, and application requirements.

How long does a cutting press machine last?

With proper maintenance, a cutting press machine can operate efficiently for many years, delivering consistent performance.

Conclusion: Your Trusted Partner for Cutting Press Machines in India

Choosing the right Cutting Press Machine is an investment in productivity, precision, and long-term reliability. Inspire Engineers combines engineering expertise, quality materials, and customer-focused design to deliver machines that perform consistently in demanding industrial environments.

As a leading cutting press machine supplier and manufacturer in Ahmedabad, we remain committed to innovation, quality, and customer satisfaction. When precision matters and performance counts, Inspire Engineers stands ready to support your industrial success—today and tomorrow.