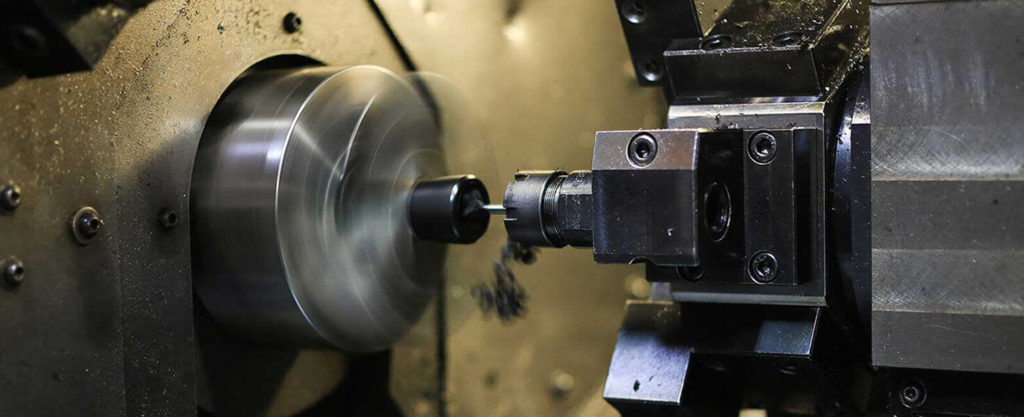

cnc swiss machining

Let’s be real—most people think CNC turning is CNC turning. One machine, spin the stock, chop it down, done. But if you’ve ever held a tiny, fiddly shaft in your hand and realized half the batch is scrap, you know there’s more to the story. That’s where CNC Swiss machining comes in. It’s not just a fancier lathe—it’s a totally different approach for small, complex parts that need crazy tight tolerances.

Traditional CNC Turning—What it Does

So, normal CNC turning: you clamp a piece of metal, it spins, and a tool cuts it down. Simple. Works great for big chunks, rods, shafts—stuff that can take a beating without bending. But here’s the thing: the longer and thinner your stock gets, the more it wants to wiggle. Even tiny vibrations, and suddenly you’ve got wobbly surfaces or parts out of spec. You can slow things down, add supports, whatever—but it’s always a compromise.

Swiss-Style Support Changes Everything

Swiss machines don’t let the bar just float there. They use a sliding bushing, right up against the workpiece, holding it steady while cutting. Tiny deflections? Forget it. This setup makes a huge difference for long, thin parts or those little pins and screws that need to fit perfectly. You get smoother surfaces, consistent tolerances, and way less scrap. If you’ve struggled with deflection on traditional lathes, this will feel like cheating.

Handling Complicated Parts Without a Headache

Here’s another kicker: Swiss machines can handle complexity in one go. Need holes, threads, maybe a slot—all on the same tiny shaft? On a regular lathe, you’re flipping, re-fixturing, praying nothing shifts. Swiss machines have multiple tools and axes, often live tooling, so you can drill, mill, and turn in a single setup. Saves time. Reduces mistakes. Keeps you sane when your parts start looking like miniature engineering puzzles.

CNC Precision Turned Components Shine Here

Let’s get specific. With Swiss machining, your CNC precision turned components come out tight, smooth, and spot-on. Threads aren’t messy, diameters don’t wander, and surfaces are consistent. Traditional turning can get close, but you often need extra setups or slow speeds. For tiny, intricate stuff—medical devices, aerospace fasteners, electronics—Swiss is basically the only option that hits the specs reliably.

Materials—Swiss loves a Challenge

Both Swiss and traditional CNC lathes can handle metals like aluminum, stainless steel, brass, and titanium. But Swiss really shines with tricky alloys—springy, tough, high-strength stuff that tends to chatter or bend on a normal lathe. The support bushing keeps it steady. So you can push harder, run faster, and still hit tolerances without babysitting the machine constantly. Saves headaches, especially when every part counts.

Speed and Efficiency—Not What you’d Expect

Some people assume traditional turning is faster. Sure, for big, simple parts, maybe. But for tiny, long, or multi-feature parts? Switzerland often beats it. One setup, continuous support, multiple tools running at once—it adds up. You crank out hundreds or thousands of pieces faster than juggling setups on a regular lathe. Plus, less scrap. Efficiency isn’t just about machine speed; it’s about how little time you waste fixing errors.

Drawbacks—let’s be Honest

Nothing’s perfect. Swiss machines are pricey. Complicated. Programming them isn’t for beginners. Maintenance? More moving parts than a standard lathe, more things to go wrong. For big, simple components, a regular lathe still wins on cost. Swiss is about precision, not brute force. So you gotta know when it’s overkill—and when it’s a lifesaver.

Choosing the Right Machine

How to decide? Size, complexity, and tolerance first. Tiny, long shafts? Swiss. Multi-feature parts that need perfect alignment? Swiss. Big, chunky rods? Regular turning works. Volume matters too—Swiss pays off when you’re doing lots of small parts. Low volume of big parts? Don’t waste the cash. The trick is matching the machine to the part, not forcing one method to do everything.

Conclusion

Bottom line: CNC precision turned components aren’t just a “nice to have”—they’re essential when you need really small, complex parts made right. Traditional CNC turning works fine for larger, simpler pieces, but when tolerances are tight or geometry gets tricky, Swiss takes the lead. Less deflection, smoother surfaces, and more consistent output—it’s why industries like aerospace, electronics, and medical devices rely on it. Know the difference, pick the right method, and save yourself a ton of headaches on the shop floor.