Precision Die Casing ensures perfect shape, smooth finish, and reliable casting accuracy

Precision Die Casing accuracy means making metal parts that look exactly like the design, without mistakes. When a metal part is accurate, it fits perfectly, works smoothly, and lasts longer. In simple terms, it is like filling a mold with clay and getting the same shape every time. In industries like automotive, electrical, and machinery, even a small error can cause big problems. This is why accuracy is very important in metal casting.

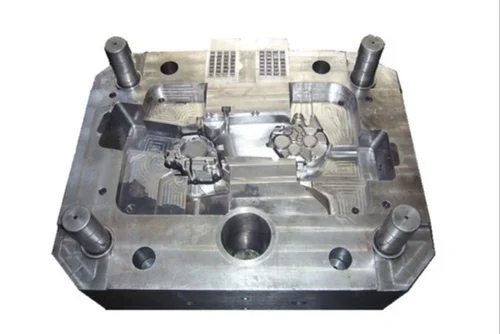

What Is a Precision Die Casing Die

A Die Casing Die is a special tool used to shape molten metal into the required form. Think of it as a strong metal box with the exact shape inside. When hot metal is poured or injected, it fills the shape and becomes a solid part after cooling. A precision Die Casing Die is made with high care so that every detail is correct. This helps in making parts that are smooth, strong, and correct in size every time.

Why Precision Matters in Die Casting

Precision is important because machines need parts that match perfectly. When the Die Casing Die is made with high accuracy, the final product comes out clean and well-shaped. There are fewer chances of cracks, rough edges, or size problems. This means less waste and less rework. Industries save time and money because they do not need to fix mistakes again and again.

How a Die Casing Die Controls Shape and Size

The main job of a Die Casing Die is to control the shape and size of the casting. When the inner cavity of the die is accurate, the molten metal flows evenly. This creates a balanced and correct shape. A good die also keeps the thickness of the metal even, which makes the part strong. When size and shape are controlled properly, the parts fit easily during assembly.

Role of Material Quality in Accuracy

The material used to make the Die Casing Die also plays a big role. Strong and heat-resistant steel helps the die stay stable during high temperatures. If the die is weak, it may change shape slightly after many uses. A high-quality Die Casing Die stays firm and gives the same result again and again. This consistency is what industries trust for large production.

How Precision Reduces Defects

Defects like air gaps, uneven surfaces, and broken edges often come from poor die quality. A precision Die Casing Die helps reduce these problems. It allows smooth metal flow and proper cooling. When cooling happens evenly, the metal does not shrink unevenly. This improves the surface finish and strength of the casting, making it ready for use without extra work.

Better Accuracy Means Better Productivity

When accuracy is high, production becomes faster. Workers do not need to check and correct each part again and again. Machines run smoothly because parts fit well. A reliable Die Casing Die helps manufacturers produce thousands of parts with the same quality. This improves overall productivity and builds trust with customers.

Importance of Expert Manufacturing

Creating a precision die needs experience, modern machines, and skilled engineers. This is where trusted manufacturers like Auto Die Cast (India) focus on quality at every step. With proper design, testing, and finishing, the die performs well for a long time. Another advantage of working with Auto Die Cast (India) is their focus on accuracy that meets industry standards.

Long-Term Benefits for Industries

Using a precision Die Casing Die gives long-term benefits. Parts last longer, machines perform better, and maintenance costs go down. Industries can deliver better products to their customers. Over time, this improves brand value and customer satisfaction. Accuracy today helps build success for the future.

Final Thoughts

A precision Die Casing Die is not just a tool, it is the heart of accurate metal casting. It controls shape, improves strength, reduces defects, and increases productivity. If you want reliable, accurate, and high-quality casting solutions that grow your business, connect with a trusted expert today and take the first step toward perfect casting results.