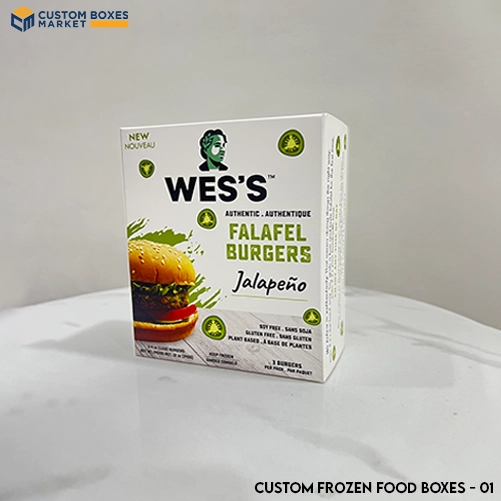

Elevate Your Brand with Custom Frozen Food Boxes Featuring Your Logo — Available Wholesale Across the UK!

In today’s competitive frozen food market, packaging does more than just protect the product — it plays a crucial role in preserving quality, maintaining safety, and building brand recognition. Custom frozen food boxes are the ideal solution for businesses looking to meet all of these needs while standing out in the freezer aisle. With consumer attention spans shrinking and shelf space becoming increasingly competitive, investing in well-designed, functional, and branded packaging is essential. Whether you’re a small food startup or an established frozen goods manufacturer, custom boxes are your gateway to better product performance and consumer trust.

What Are Custom Frozen Food Boxes?

Packaging solutions specifically designed to protect food items in freezing temperatures, Custom Frozen Food Boxes are made from moisture-resistant, food-safe materials such as coated paperboard or corrugated cardboard. These boxes are tailored in size, structure, printing, and design to match your specific product needs — whether it’s frozen vegetables, ready-to-eat meals, desserts, or meat. But custom frozen food packaging isn’t just functional. It also serves as a marketing tool that communicates your brand identity, product quality, and nutritional value to consumers.

Why Custom Packaging Matters for Frozen Foods

Frozen food packaging has unique requirements that generic boxes simply can’t meet. Here’s why custom frozen food boxes make all the difference:

1. Temperature and Moisture Resistance

These boxes are engineered to withstand sub-zero temperatures without losing shape or structure. They often feature special coatings that prevent moisture absorption and freezer burn, ensuring your product remains intact from freezer to table.

2. Brand Recognition and Shelf Appeal

The freezer aisle is packed with similar products. Eye-catching, customized packaging helps your brand stand out and increases the likelihood of purchase. A strong visual identity — through color, typography, and design — builds brand familiarity and consumer trust.

3. Informative and Compliant Labeling

Custom packaging allows you to clearly print nutritional facts, cooking instructions, certifications (like organic or gluten-free), barcodes, and expiration dates, all in compliance with food safety regulations.

4. Product Protection

Strong, insulated packaging reduces the risk of contamination, breakage, or spoilage during transit and storage, helping to maintain product integrity and minimize returns.

5. Eco-Friendly Options

Sustainable materials and biodegradable coatings are now available for custom frozen food boxes, giving environmentally conscious brands the opportunity to align packaging with their values.

Popular Types of Frozen Food Boxes

Depending on your product and branding goals, there are various types of custom packaging options available:

• Tuck-End Boxes

Ideal for lightweight frozen items like snacks or desserts. These are easy to assemble and can be printed with high-quality graphics.

• Sleeve Packaging

Used for trays or microwavable meals. The sleeve wraps around the container and offers plenty of space for branding and instructions.

• Seal-End Boxes

Commonly used for heavier frozen products, offering extra security and durability during shipping.

• Die-Cut Window Boxes

Feature transparent windows that let customers view the product without opening the package — excellent for visually appealing items like frozen cakes or gourmet meals.

• Corrugated Boxes

Perfect for bulk frozen shipments, such as wholesale orders. Strong and protective, these can be customized with branding and shipping information.

Materials Used in Custom Frozen Food Packaging

Custom frozen food boxes require materials that can withstand low temperatures and moisture while maintaining print quality and structural integrity. Common materials include:

- Kraft Paperboard: Eco-friendly, recyclable, and durable. Suitable for brands prioritizing sustainability.

- Coated Paperboard: Offers a smooth finish and moisture resistance, ideal for vibrant printing and freezer storage.

- Corrugated Cardboard: Best for heavy or bulk items. Insulated versions are available for extended cold storage.

- Metalized Films or Linings: Occasionally used for added thermal resistance and barrier protection.

Printing and Finishing Options

High-quality printing and finishing elevate your packaging from functional to exceptional. Options include:

- Offset and Digital Printing

For clear, sharp images and vibrant colors. - Matte or Gloss Lamination

Enhances appearance and provides moisture protection. - UV Coating

Adds shine and durability. - Embossing/Debossing

Adds texture to logos or key design elements. - Foil Stamping

Perfect for luxury frozen items or premium branding.

Design Considerations for Custom Frozen Food Boxes

A great box design is about more than just aesthetics. It’s about function, clarity, and appeal. When designing your packaging, consider the following:

- Typography: Use bold, readable fonts for key information.

- Color Psychology: Cool tones suggest freshness; warm tones evoke comfort foods.

- Imagery: High-resolution photos of the prepared dish can boost appetite appeal.

- Clear Branding: Your logo, colors, and messaging should be consistent and recognizable.

- Instructions: Easy-to-follow preparation or heating instructions are a must.

Applications Across Different Industries

Custom frozen food boxes are essential for a wide range of frozen goods, including:

- Frozen dinners and ready meals

- Ice cream and frozen desserts

- Frozen fruits and vegetables

- Meat, poultry, and seafood

- Frozen bakery items

- Plant-based and vegan frozen meals

- Kids’ meals and lunchboxes

- Ethnic or specialty frozen cuisines

FAQs

Q1: Are custom frozen food boxes recyclable?

A: Yes, many are made from recyclable paperboard or cardboard. You can also opt for eco-friendly coatings and inks to improve sustainability.

Q2: Can I include a transparent window in my frozen food box?

A: Absolutely. Die-cut windows made with freezer-safe clear films allow consumers to see the product while maintaining packaging integrity.

Q3: What printing method is best for frozen food boxes?

A: Offset printing is widely used for its sharp quality, but digital printing is ideal for short runs and prototypes.

Conclusion

More than just containers, effective packaging is a critical part of your product’s success. From protecting food in extreme conditions to conveying your brand’s message on crowded shelves, solutions like those from Custom Boxes packaging Experts help deliver both performance and shelf appeal — giving your brand the competitive edge it needs in today’s demanding frozen food industry. Whether you’re launching a new product or refreshing your brand, investing in high-quality, well-designed frozen food boxes is a smart move. With customizable shapes, eco-friendly materials, and eye-catching designs, you can deliver both freshness and visual appeal — straight from the freezer to your customer’s table.