hemp cutting board

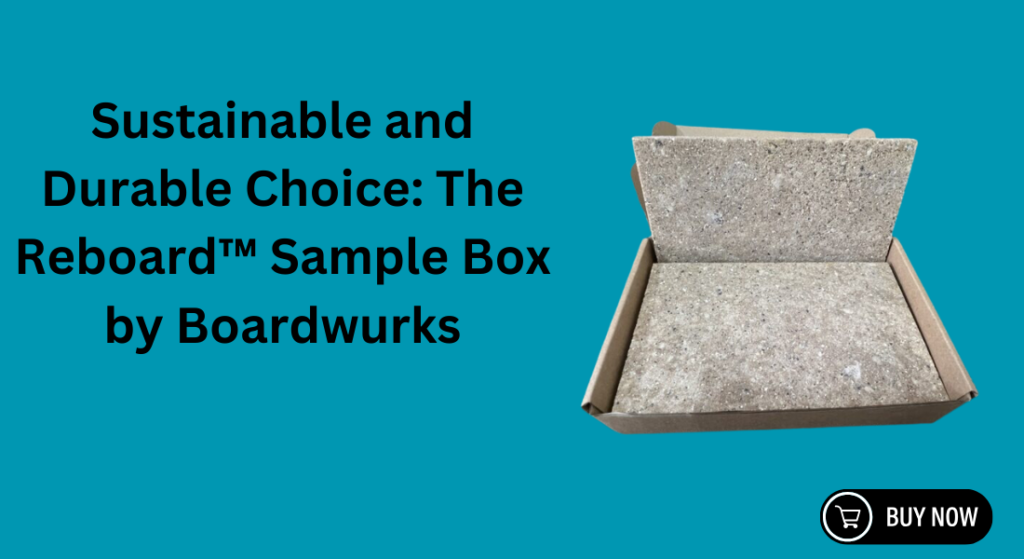

As a leading player in sustainable building materials, Boardwurks introduces the innovative Reboard™ Sample Box—a carbon-smart solution for construction industries and environmentally conscious consumers. Engineered with recycled materials and sustainable methods, this hemp cutting board is more than just an eco-friendly option; it sets new standards in durability, versatility, and environmental responsibility. This guide highlights why Reboard is your ideal choice for eco-conscious construction while using each keyword to ensure this product reaches those searching for environmentally responsible solutions.

What is Reboard and Why Choose It?

Reboard is a next-generation material engineered by combining waste fiberglass laminate (FRP), often sourced from boat manufacturing and decommissioned wind blades, with a non-formaldehyde binding agent. This process not only minimizes waste but produces an engineered panel made with 95% recycled content. As a result, the material not only avoids contributing to landfills but offers a closed-loop solution—its fully recyclable nature creates a true circular economy. It’s ideal for industries that prioritize sustainability, especially in sectors like marine and building materials, where durable, high-density materials are essential.

Boardwurks recognizes the need for greener solutions, and Reboard was designed with this purpose in mind. Its sustainable composition and recyclable properties make it an ideal choice for eco-friendly projects across industries.

Benefits of Reboard for Sustainable Building

For those interested in reducing environmental impact, Reboard offers significant advantages. This product aligns with global sustainability initiatives, making it a superb option for both commercial and residential applications. Here’s a look at why Reboard is the future of sustainable building:

- Made from 95% Recycled Content: By reusing fiberglass laminate (FRP) waste, Reboard not only repurposes materials but contributes to a significant reduction in landfill waste.

- Non-Formaldehyde Binding Agent: Reboard’s construction uses a non-toxic binding agent, ensuring the material is safe for both installers and occupants.

- Lightweight Yet Durable: Despite being lightweight, Reboard offers high structural integrity and is built to withstand demanding applications.

- Fully Recyclable: Reboard is engineered for end-of-life recycling, making it one of the few products in its category to support a fully circular economy.

- Cost-Effective: Compared to traditional panels, Reboard offers a more economical solution without sacrificing quality or performance.

Applications of Reboard in Various Industries

Reboard has found its place in multiple industries, thanks to its unique characteristics. Its eco-conscious design and adaptability make it suitable for a range of applications, from marine and building materials to creative uses in interior design.

- Marine Industry: The marine sector requires materials that can handle exposure to elements, making Reboard an ideal choice. It provides an economical and environmentally sound option for boat manufacturing and repairs.

- Building Materials: Reboard’s strength and light weight make it a great option for eco-friendly building projects, whether residential, commercial, or industrial.

- Furniture and Interior Design: For those creating eco-friendly interiors, Reboard offers a sustainable alternative for countertops, walls, and flooring.

Why Hemp in the Reboard Sample Box?

In response to the growing need for eco-friendly materials, hemp is becoming an increasingly popular choice due to its durability and sustainability. This hemp cutting board and other hemp pallets provide a high-quality, biodegradable option that aligns with sustainable initiatives. By incorporating hemp into Reboard’s design, Boardwurks meets the demands of green construction, providing a material that is not only functional but also responsible.

How Reboard Stands Out from Traditional Materials

Unlike conventional building panels, Reboard is designed with a strong focus on sustainability and performance. Its materials are sourced from waste FRP, and it incorporates a non-formaldehyde binding agent, making it far safer for the environment. Furthermore, its recyclability significantly reduces the overall carbon footprint of any project using this product.

Reboard also provides a cost-effective alternative to medium- and high-density panels, making it accessible to various industries looking for durable, sustainable materials without breaking the budget. Whether you’re involved in a large-scale building project or a smaller marine installation, Reboards versatility ensures it meets rigorous requirements while supporting green initiatives.

Key Features of the Reboard Sample Box by Boardwurks

- Eco-Friendly Composition: 95% recycled content from waste FRP.

- Non-Formaldehyde Binding: Ensures safe handling and usage in projects.

- Fully Recyclable: Aligns with circular economy principles.

- Cost-Effective: An affordable alternative for high-density applications.

- Lightweight with High Structural Integrity: Combines ease of use with robustness.

For those interested in exploring the potential of Reboard, Boardwurks offers the Reboard Sample Box, allowing you to evaluate this revolutionary material firsthand. Its sustainable construction is complemented by durable features, making it a strong candidate for any project prioritizing eco-friendly materials.

Frequently Asked Questions (FAQs)

- What is the Reboard Sample Box?

The Reboard Sample Box by Boardwurks is a sample pack featuring Reboard, a carbon-smart, recyclable building material made from 95% recycled content. It’s a sustainable alternative for high-density building materials. - How is Reboard sustainable?

Reboard is made primarily from waste FRP from boat manufacturing and wind blades, combined with a non-formaldehyde binding agent. This composition makes it both eco-friendly and recyclable, promoting a closed-loop economy. - In what industries is Reboard commonly used?

Reboard is widely used in marine, building materials, and even interior design sectors, thanks to its durability, eco-friendliness, and cost-effectiveness. - What are the main benefits of using Reboard over traditional panels?

Reboard provides a sustainable, lightweight, cost-effective, and recyclable option compared to traditional medium- and high-density panels, making it an ideal choice for eco-conscious projects. - Can I use Reboard in marine applications?

Yes, Reboard’s composition makes it suitable for marine use, particularly in boat manufacturing and repairs. It’s durable and lightweight, ideal for various marine applications.

Product Tags: hemp cutting board, re-board, material reboard, reboards, material the reboard, re-board material, hemp pallets