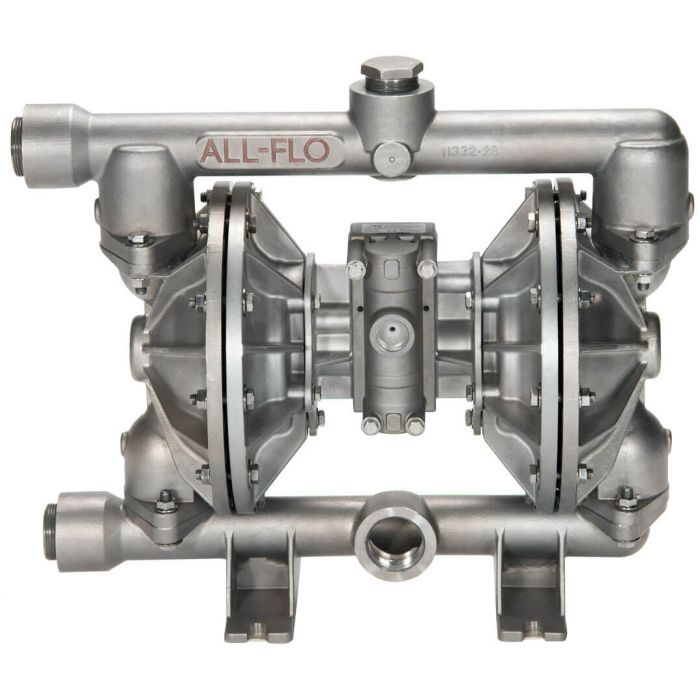

Air Operated Diaphragm Pump

The Rise of Flexible Pumping Solutions

The modern day industrial needs require equipment that can be adjusted quickly, be safe and manage unforeseen situations without failure. It is at this point that the air operated diaphragm pump has cut a niche in industries. Its flexibility and reliability make it a favourite in fluid transfer systems in the present day despite its use in chemical handling, and food processing.

An air operated diaphragm pump in contrast to the conventional pumps uses compressed air to move the fluids. This is the mechanism which is simple and yet powerful to enable it to deal with aggressive, viscous or sensitive liquids easily. Demand of AODD Pump solutions keeps on increasing as industries seek safer and more efficient operations.

How Air Operated Diaphragm Pump Technology Delivers Control

The difference with an air operated diaphragm pump is that it provides control in a very specific way without complicated electronics. Pumping action is based on the movement of the diaphragms between the back and forth motion which makes the process of forming suction and discharge processes to maintain fluid flow intact and predictable.

The design of the AODD Pump is suitable in the circumstances where electrical pumps could have risks or limitations.

Air Powered Design That Enhances Safety

The air operated diaphragm pump also avoids the possibility of sparks by virtue of its functioning on compressed air. This renders it suitable in the risky areas like oil plants, chemical plants and paint industries. There is no afterthought about safety, and it is embedded.

Boosting Reliability in Harsh Operating Conditions

The world of industry is inhuman. The air operated diaphragm pump is constructed such that it is able to survive under such pressures. The simplicity of its construction minimizes the points of mechanical failures and can easily be used even in harsh environments.

The reason why many industries use AODD Pump is that it has the capability of continuing to run where others fail.

Handling Abrasive and Viscous Fluids With Ease

Thick slurries and corrosive chemicals are pumped using an air operated diaphragm pump without having to affect performance. The diaphragm forms a closed chamber decreasing wear and increasing the duration of operation.

Efficiency That Adapts to Real World Demands

Efficiency is not only about speed. It is about control, consistency, and adaptability. Pressure can be easily lowered or increased so that the flow rate of an air operated diaphragm pump is easy to adjust. This enables the operators to optimize performance without halting the system.

Smooth Flow Control Without Complex Systems

The air operated diaphragm pump does not use electronic controllers but it reacts immediately to changes in air supply. This leads to a pumping experience that is smooth and responsive and that is in line with changing operational demands.

Maintenance Simplicity That Saves Time

Downtime is expensive. A major advantage of an air operated diaphragm pump is that it requires minimum maintenance. Servicing is quicker and less expensive since most of the parts are few and internal parts can be easily accessed.

This is a simplicity that makes the operations continue without extended pauses.

Quick Servicing for Continuous Operations

Without special tools, diaphragms and valves may be replaced. This implies that maintenance teams are able to respond fast and reduce the time spent and increase the life span of equipment.

AODD Pump Applications Across Multiple Industries

AODD Pump has received extensive usage in different industries due to its flexibility. It is used in chemical processing plants in safe transfer of fluids. The hygienic operation is appreciated by the food and beverage industries. Mining and construction companies rely on it to work with abrasive substance. All the applications are characterized by the same fundamental strengths, flexibility, safety, and reliability.

From Chemicals to Clean Fluids

A diaphragm pump that is operated by air has the capability of working with both aggressive chemicals and food grade liquids that are delicate. This broad area of use brings it as an intelligent long term investment in business with a goal of growing.

Energy Efficiency Supporting Sustainable Operations

Sustainability is emerging as one of the major considerations in equipment choices. The air operated diaphragm pump also helps as it can only work when there is the supply of air. No wasted energy usage, and, therefore, minimizes the total operation expenses.

This on demand capability is in line with the current efficiency objectives.

Optimized Air Usage for Better Performance

The enhanced designs will guarantee effective use of air without compromising the production. This is the balance that enhances productivity and maintains the energy usage at a check.

Future Trends Shaping AODD Pump Performance

Due to the progression into the smarter systems in industries, the air operated diaphragm pump designs are changing. Manufacturers are targeting on better materials, less noisy operation and better sealing technologies.

It is no longer the case that the AODD Pump is a backup solution. It is also emerging as one of the major options to operations that require reliability, safety, and flexibility. The air operated diaphragm pump is still in use today providing industrial flow in various applications due to its proven workability and future ready design.