Rubber Molding Machine Manufacturer in India – Inspire Engineers

Top Rubber Molding Machine Manufacturer

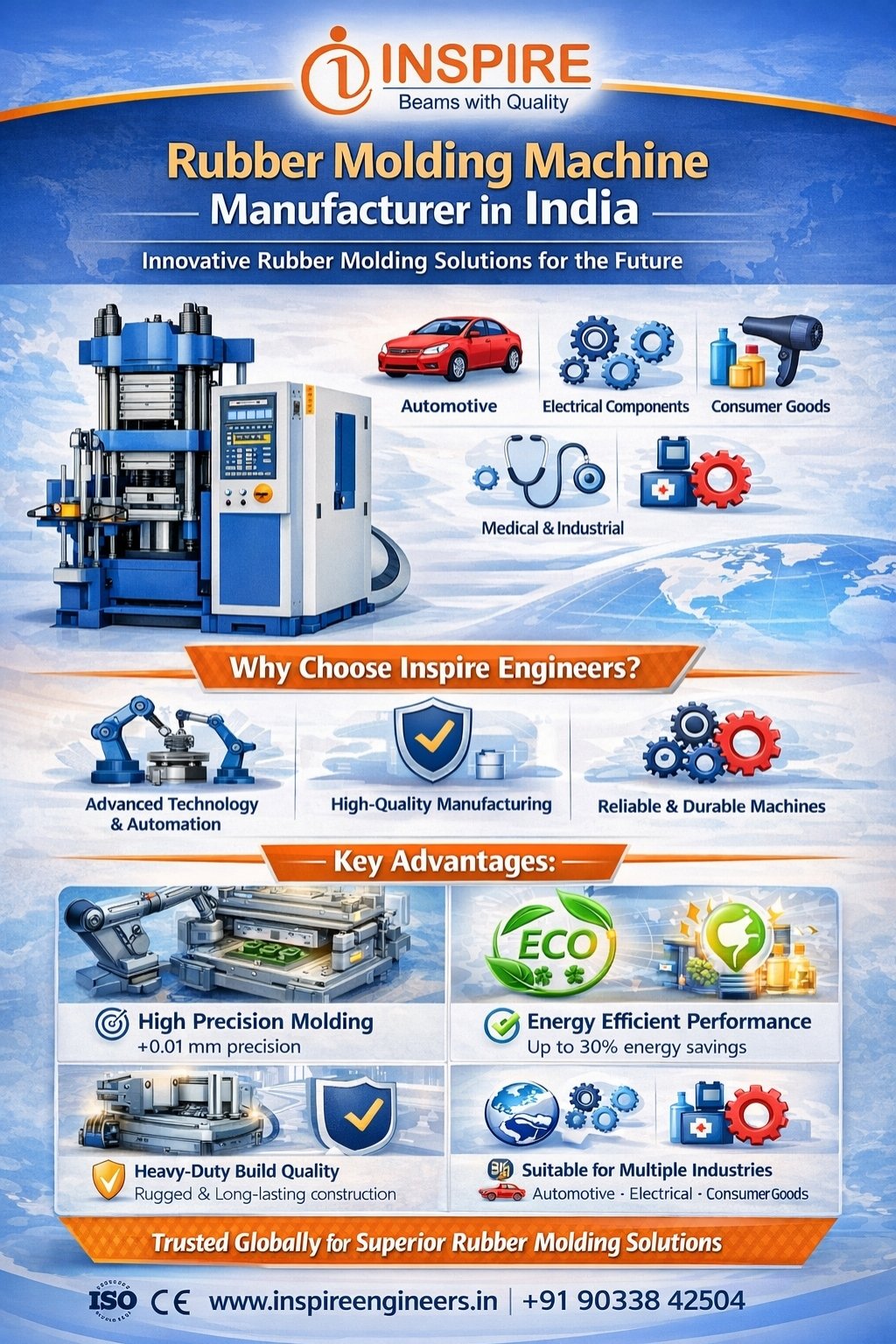

In today’s competitive industrial landscape, businesses are continually seeking ways to optimize production processes. The Rubber Molding Machine has become an essential tool in a wide range of manufacturing industries, from automotive to medical equipment. As a leading manufacturer in India, Inspire Engineers has established itself as a trusted name in providing cutting-edge rubber molding solutions that deliver precision, durability, and operational efficiency.

What is a Rubber Molding Machine?

A Rubber Molding Machine is a specialized machine used in the production of rubber parts and components. These machines are designed to mold rubber into specific shapes and sizes through various processes such as compression molding, injection molding, and transfer molding. The primary purpose of these machines is to create consistent, high-quality rubber products used in multiple industries.

Rubber molding is essential for creating products that require high durability, flexibility, and strength. Common applications include automotive parts, seals, gaskets, electrical components, and medical devices. The increasing demand for precision-engineered rubber products has made the Rubber Molding Machine a critical part of modern manufacturing.

Why Choose Inspire Engineers for Your Rubber Molding Solutions?

At Inspire Engineers, we are committed to offering the best-in-class rubber molding machinery that meets the highest industry standards. Here’s why our machines are the preferred choice for businesses around the world:

1. Precision-Engineered Performance

Each Rubber Molding Machine we manufacture is built with precision engineering, ensuring that every product molded is uniform and meets the required specifications. The technology we use guarantees accurate molding outputs that enhance the overall quality of your products. Whether you’re manufacturing small-scale components or large industrial parts, our machines ensure the consistency of every mold.

2. Energy-Efficient and Cost-Effective

Energy efficiency is at the core of every rubber molding machine we create. We understand that operating costs can add up quickly, which is why we have designed our machines to minimize energy consumption while maximizing productivity. By integrating energy-efficient features, we help reduce operational costs without compromising on performance.

In today’s market, cost-effective machinery that delivers high performance is key to staying competitive. Our Rubber Molding Machines provide you with the perfect balance of affordability and high-quality output, ensuring maximum return on investment.

3. Durability and Long-Term Performance

We use only premium-grade materials in the manufacturing of our rubber molding machines. This ensures that our machines are not only durable but also capable of delivering high performance for an extended period. The robust structural design and high-quality materials used in our machines help minimize wear and tear, ensuring that the machines can withstand continuous use in harsh production environments.

4. Low Maintenance and Smooth Operation

One of the significant advantages of our Rubber Molding Machines is their low maintenance requirements. Designed for easy servicing and minimal downtime, our machines are built to operate smoothly for longer periods without frequent interruptions. With intuitive controls and efficient design, our machines ensure that your production process remains hassle-free.

5. Suitable for Diverse Industrial Applications

The versatility of our rubber molding machines is a key selling point. Whether you’re in the automotive, medical, or electrical components industry, our machines can be tailored to meet your specific requirements. From seals and gaskets to medical components and electrical parts, we provide flexible solutions that suit various industrial needs.

Key Advantages of Using a Rubber Molding Machine

In the competitive world of manufacturing, Rubber Molding Machines offer several advantages that make them a worthwhile investment. Here’s a breakdown of the top benefits:

Precision and Consistency

Precision is crucial when it comes to manufacturing rubber products. Whether creating parts for the automotive industry or electrical components, our Rubber Molding Machines ensure that every product is produced with exact specifications. This consistency leads to higher product quality and fewer defects, which reduces waste and increases productivity.

Improved Production Speed

Another significant advantage of utilizing a Rubber Molding Machine is the enhanced production speed. These machines are engineered to manage high production volumes while ensuring precise results. By automating the molding process, manufacturers can efficiently produce large quantities of components, improving overall productivity.

Reduced Operational Costs

Operating a Rubber Molding Machine is a cost-effective solution. The energy-efficient features of our machines help reduce power consumption, while the long-lasting durability minimizes the need for frequent repairs and replacements. This combination of factors makes rubber molding machines a great choice for businesses seeking to lower their operational costs.

Customization for Specific Needs

Every industry has different molding requirements, and our Rubber Molding Machines are built with flexibility in mind. Whether you need to produce small, intricate parts or large, heavy-duty components, we offer machines that can be customized to suit your needs. This adaptability makes our machines a perfect fit for a wide range of industrial applications.

How Rubber Molding Machines are Used in Various Industries

Automotive Industry

The automotive industry relies heavily on rubber products, from tires to seals and gaskets. Rubber Molding Machines are used to produce these components with high precision, ensuring that every part meets the industry’s strict standards for performance and safety. By using our machines, automotive manufacturers can achieve consistent product quality and increase production efficiency.

Electrical and Electronics Industry

In the electrical and electronics industry, rubber parts such as seals, gaskets, and insulating materials are essential for ensuring the functionality and safety of electrical devices. Rubber Molding Machines allow manufacturers to create these components with high accuracy, ensuring reliable performance even in demanding environments.

Medical Industry

The medical industry demands high-quality, sterile, and durable rubber products for applications such as medical devices, seals, and tubing. Our Rubber Molding Machines are designed to meet the stringent quality standards required in this sector, ensuring that every product is safe, reliable, and durable.

Consumer Goods Industry

Rubber products are also widely used in the consumer goods industry for various applications, including kitchen appliances, toys, and sports equipment. The versatility of Rubber Molding Machines allows manufacturers to produce high-quality rubber products for everyday use, contributing to the comfort and safety of consumers.

Conclusion: Why Choose Inspire Engineers for Your Rubber Molding Needs

At Inspire Engineers, we are committed to providing best-in-class Rubber Molding Machines that are designed to meet the specific needs of various industries. With a focus on precision, energy efficiency, and durability, our machines deliver high-quality results that improve production efficiency while minimizing operational costs.

Whether you’re in the automotive, medical, or consumer goods industry, our Rubber Molding Machines offer the flexibility and performance you need to stay competitive in today’s fast-paced manufacturing world. Trust Inspire Engineers for all your rubber molding machine requirements, and experience the difference in quality and performance.