In today’s fast-paced manufacturing world, even a small leak can lead to major problems. Production delays, equipment damage, safety risks, and rising operational costs — all of these can stem from something as simple as an undetected coolant leak. That’s why manufacturers across industries are turning toward smarter leak detection solutions.

But the real question is: Is WeldSaver the future of leak detection in manufacturing?

Let’s explore why this advanced technology is gaining serious attention and how it may completely transform modern production environments.

The Growing Problem of Leaks in Manufacturing

Leak detection might not sound glamorous, but it plays a critical role in manufacturing performance. Whether in automotive plants, welding operations, robotic production lines, or heavy industrial facilities, water and coolant systems are essential.

When leaks occur, the consequences can include:

-

Equipment damage

-

Costly downtime

-

Electrical hazards

-

Contaminated production lines

-

Increased maintenance costs

-

Decreased productivity

Traditional leak detection methods often rely on manual inspection or delayed alerts. By the time someone identifies the issue, the damage may already be done. In highly automated production facilities, that delay can cost thousands — sometimes even millions — of dollars.

Manufacturers need faster, smarter, and more reliable systems. That’s where WeldSaver enters the picture.

What Is WeldSaver?

WeldSaver is an advanced leak detection and containment system designed specifically for industrial and robotic welding environments. It monitors coolant flow in real time and immediately detects abnormalities that indicate leaks, hose failures, or component damage.

Instead of waiting for visible signs of leakage, WeldSaver acts instantly.

The system can:

-

Monitor coolant flow rates

-

Detect hose bursts or slow leaks

-

Shut off coolant supply automatically

-

Send alerts to operators

-

Prevent damage before it spreads

In modern automated facilities, this level of intelligent monitoring is no longer a luxury — it’s becoming a necessity.

Why Traditional Leak Detection Is No Longer Enough

In the past, leak detection often relied on:

-

Visual inspections

-

Manual maintenance checks

-

Basic pressure sensors

-

Reactive maintenance strategies

The problem? These methods are reactive rather than proactive. By the time a leak is visible or measurable, damage may already be significant.

Manufacturing is evolving rapidly with Industry 4.0 technologies. Smart factories demand:

-

Real-time monitoring

-

Automated response systems

-

Data-driven insights

-

Predictive maintenance

WeldSaver aligns perfectly with these modern needs.

Key Benefits of WeldSaver in Manufacturing

1. Immediate Leak Detection

WeldSaver detects leaks within seconds. The system continuously monitors coolant flow and identifies abnormalities instantly.

This rapid detection prevents:

-

Weld gun failures

-

Electrical short circuits

-

Coolant contamination

-

Expensive machine repairs

Time is money in manufacturing — and WeldSaver saves both.

2. Automatic Shut-Off Protection

One of WeldSaver’s most powerful features is its automatic shut-off capability. When a leak is detected, the system immediately stops coolant flow.

This prevents:

-

Flooding on production floors

-

Damage to surrounding equipment

-

Slippery and hazardous work environments

-

Major production disruptions

Instead of responding after the problem spreads, WeldSaver stops it at the source.

3. Reduced Downtime

Unplanned downtime is one of the biggest financial drains in manufacturing. A single robotic welding cell failure can halt an entire production line.

By detecting leaks early and isolating issues, WeldSaver helps reduce unexpected shutdowns and ensures production continuity.

Manufacturers report significant reductions in downtime after implementing smart leak detection systems.

4. Lower Maintenance Costs

When leaks go undetected, they often lead to larger mechanical failures. Motors burn out. Electronics get damaged. Components corrode.

With WeldSaver, maintenance becomes proactive rather than reactive.

Benefits include:

-

Fewer emergency repairs

-

Longer equipment lifespan

-

Lower part replacement costs

-

Better maintenance scheduling

Over time, these savings add up substantially.

5. Improved Workplace Safety

Safety is a top priority in every manufacturing facility. Coolant leaks can create slippery floors and electrical hazards, increasing the risk of workplace accidents.

By instantly detecting and stopping leaks, WeldSaver enhances overall plant safety and reduces potential liability risks.

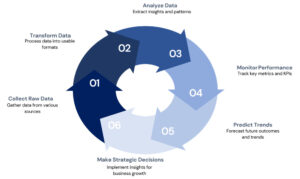

How WeldSaver Supports Industry 4.0

Industry 4.0 focuses on automation, connectivity, and smart data usage. WeldSaver integrates seamlessly into these smart manufacturing ecosystems.

It provides:

-

Real-time performance data

-

Flow monitoring analytics

-

System alerts and diagnostics

-

Integration with PLC and robotic systems

This means managers can monitor leak detection performance remotely and make informed decisions based on real-time data.

Smart factories require smart protection — and WeldSaver delivers exactly that.

Industries Benefiting from WeldSaver

WeldSaver technology is particularly valuable in industries such as:

Automotive Manufacturing

Robotic welding cells are common in automotive plants. Even a minor coolant leak can halt vehicle assembly. WeldSaver protects welding equipment and ensures uninterrupted production.

Aerospace Manufacturing

Precision and safety are critical in aerospace production. Leak detection systems like WeldSaver help maintain strict quality and safety standards.

Heavy Equipment Manufacturing

Large-scale machinery requires powerful welding systems. WeldSaver protects high-value equipment from coolant damage.

Industrial Automation Facilities

Any facility using robotic welding arms can benefit from smart leak detection solutions.

Is WeldSaver Cost-Effective?

Many manufacturers initially wonder about the investment cost of implementing WeldSaver systems.

However, when compared to the cost of:

-

Equipment damage

-

Production downtime

-

Emergency maintenance

-

Safety incidents

WeldSaver quickly proves its value.

Even preventing one major coolant failure can justify the system’s cost.

In fact, many facilities report strong ROI within a short period after installation.

Why Manufacturers Are Switching to WeldSaver

Manufacturing leaders are constantly searching for ways to:

-

Improve efficiency

-

Reduce operational risk

-

Increase equipment lifespan

-

Optimize maintenance processes

WeldSaver supports all these goals.

Its ability to detect leaks in seconds and automatically shut off coolant flow gives manufacturers peace of mind. Instead of worrying about unexpected failures, teams can focus on improving productivity and performance.

The Future of Leak Detection Technology

As manufacturing continues to evolve, leak detection systems will become even smarter.

We can expect future innovations such as:

-

AI-powered predictive leak analysis

-

Cloud-based performance dashboards

-

Advanced data reporting

-

Greater integration with IoT systems

WeldSaver is already positioned at the forefront of this transformation.

By combining real-time monitoring, automated response, and intelligent design, it sets the standard for what modern leak detection should look like.

Challenges to Consider

No system is perfect, and proper implementation is important.

Manufacturers should:

-

Ensure proper installation

-

Train maintenance teams

-

Integrate with existing automation systems

-

Regularly monitor performance data

With correct setup and maintenance, WeldSaver performs at its highest potential.

So, Is WeldSaver the Future?

When evaluating modern manufacturing needs, the answer becomes clearer.

Leak detection can no longer be an afterthought. In highly automated, high-speed production environments, immediate response systems are critical.

WeldSaver offers:

-

Speed

-

Automation

-

Intelligence

-

Safety

-

Cost savings

It transforms leak detection from a reactive maintenance task into a proactive protection strategy.

For manufacturers looking to future-proof their facilities, smart leak detection systems are not optional — they are essential.

Final Thoughts

Manufacturing is becoming smarter, faster, and more automated every year. With that progress comes greater responsibility to protect equipment, maintain safety, and reduce operational risk.

WeldSaver represents a significant step forward in leak detection technology. By delivering real-time monitoring, automatic shut-off capabilities, and integration with smart factory systems, it aligns perfectly with the future of manufacturing.

If your facility relies on robotic welding, coolant systems, or automated production lines, it may be time to consider whether your current leak detection methods are enough.

Because in modern manufacturing, prevention is always better — and more profitable — than repair.

Call to ActionWant to learn more about how this technology works and how it can protect your production line?

Explore the Proteus Industries today and discover how advanced leak detection can transform your manufacturing efficiency, safety, and profitability.

The future of leak detection may already be here — and it’s smarter than ever.